Our Blog

This is our blog.. please read on

I don't think anything beats solid wood in terms of appearance. Whether painted or finished with a translucent coating to showcase a particular species, wood really sets the tone.

One of the most important—and often overlooked—aspects of an entrance door is the tactile experience. Warm, solid, reassuring, and strong is something you experience with a solid wood door. I personally don't experience those things with other materials. You feel the weight of a solid timber door as you open and close it—it’s a reassuring experience.

Plastic, aluminium and other materials do have their place, but for an authentic period home, timber windows are essential.

I've shared quite a few of our recent projects on the blog and the gallery section of ou

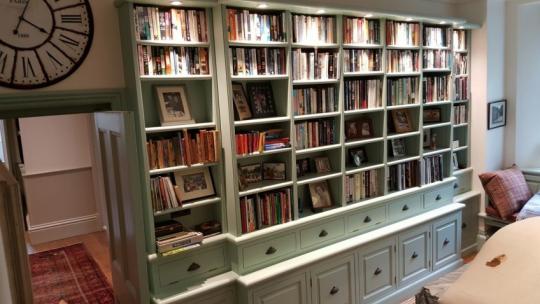

This is the second time we've worked on the same bookcase.

Slim double glazing has been around for a while now and it's prominence within joinery and the construction industry was raised during a 2009 episo

The question "What do you think you could do with these shutters?" or "Do you think you can make these old shutters work?" are some of the hardest

I've learned through experience that writing off architects and designers ideas is often a mistake.

When presented with the instruction from one of our best clients, that they'd like us to make a table top from Cedar of Lebanon, I was taken aback.

You wait ages for someone to ask you sharpen their saws and then two jobs come along at once.

It's not often we get the chance to use home grown timbers in our joinery work.

Due to the poor condition of the chairs I posted about last time I'm not sure just h