Our Blog

This is our blog.. please read on

I don't think anything beats solid wood in terms of appearance. Whether painted or finished with a translucent coating to showcase a particular species, wood really sets the tone.

One of the most important—and often overlooked—aspects of an entrance door is the tactile experience. Warm, solid, reassuring, and strong is something you experience with a solid wood door. I personally don't experience those things with other materials. You feel the weight of a solid timber door as you open and close it—it’s a reassuring experience.

Introduction:

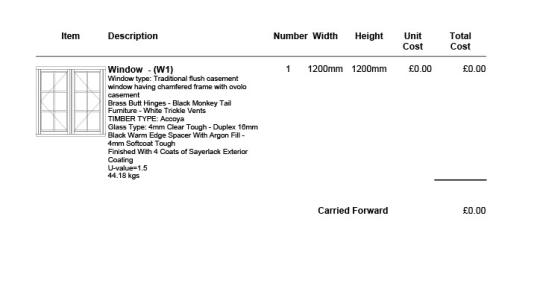

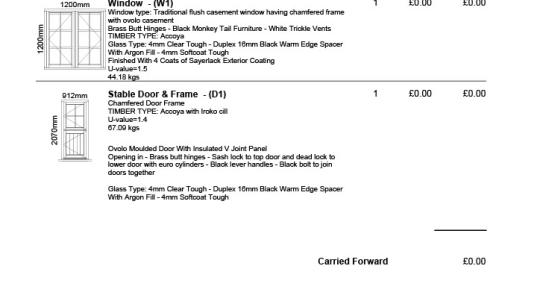

Accoya wood is renowned for its exceptional qualities in the realm of timber windows and doors.

Softwood or what many people call pine, which in most cases means European Redwood, is an "appropriate" choice for wooden windows and doors but we

I didn't know how to define this, but "Critical Path Joinery" seemed as accurate as I could get. What do I mean by that?

Clients can often be surprised at the lead times for custom or bespoke joinery.

Having new windows or any type of purpose made joinery made and installed is a relatively expensive and time consuming process.

Georgian-style sash wood windows are a common site in the UK.